Chip expressions used to determine Chip Device from a Texas Instrument white paper on junction temperatures, ultimately determining junction temperature >> device based on power. The actual chip junction temperature may differ depending on parameters entered below, especially Theta_CS => case to heatsink or vapor chamber; previously discussed.

Steps outlined:

• Measure the case temperature using the method described above.

• Measure ambient temperature (outside of the enclosure).

• Measure total power consumption of the processor in the finalized application.

• Measure the static power consumption of the processor at the case temperature measured in step1.

• Calculate the active power consumption of the processor in the finalized application. ACTIVE power = Total power – Static power

• Calculate θJA, effective of the finalized system using the following equation:

TC TA = TotalPower * TJA, effective temperature measured in step 1.

• Recalculate the maximum total power consumption of the processor.

Max TotalPower = ActivePower (step5) + Max Static power (step7)

• Recalculate the case temperature, accounting for maximum total power consumption.

TC ≈ TA (step2) + (TotalPower(step8) × θJA,effective (step6))

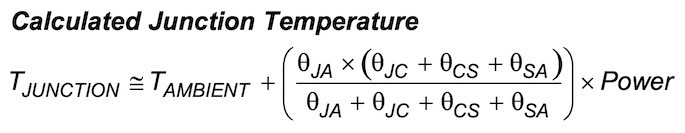

NOTE: The max case temperature measurement should account for worst case ambient conditions for the specific application. Junction temperature expression, also detailed in TI thermal expression white paper:

This sequence shows that Temperature Ambient (TA) does not need to be added in TC, rather can be accounted directly in ActivePower. Attached is an example model that incorporates Average processor power with ambient temperature. Model assumptions, plus expressions:

TAmbient = 40 C

Theta_JA = 21.62°C/W

Theta_JC = 20°C/W

Theta_CS = 0.8°C/W

Theta_SA = 20°C/W

Theta_Sum = Theta_JC + Theta_CS + Theta_SA

T_Junction_Numerator = Theta_JA * Theta_Sum

T_Junction_Denominator = Theta_JA + Theta_Sum

T_Junction = TAmbient +((T_Junction_Numerator/T_Junction_Denominator)*Power)

This is a static calculation based on current model Processor_1 power; not finite element analysis. You should get permission to re-print TI article as a reference.

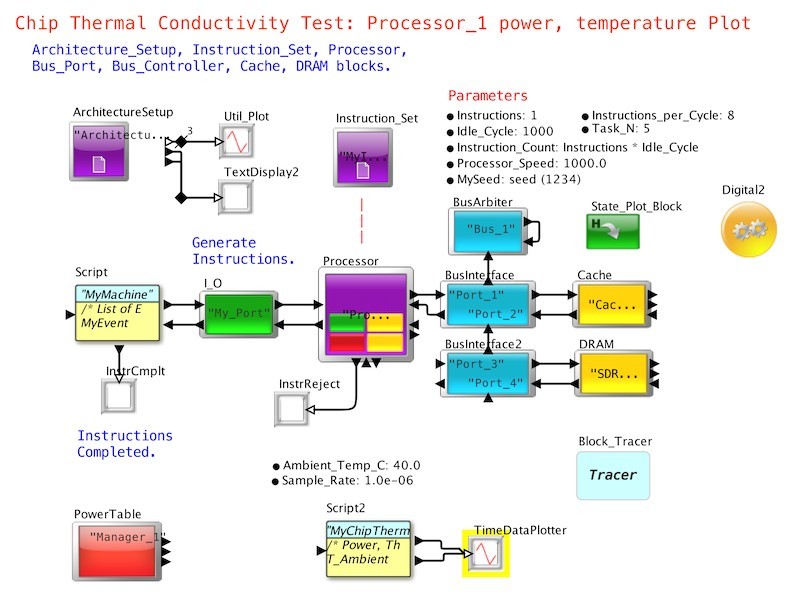

Model with single Processor model:

Model MyChipThermal Script for power, thermal; based on Sample_Rate (1 us), Ambient_Temp_C (40.0 C):

/* Power, Thermal. */

TAmbient = Ambient_Temp_C // 40.0 C

Theta_JC = 20.0 // junction to case C / W, estd

Theta_CS = 0.8 // case to heatsink C / W, estd

Theta_SA = 20.0 // heatsink to ambient C / W, estd

Theta_JA = 21.62 // junction to ambient temp C / W, estd

while (true) {

WAIT (Sample_Rate)

PM_DS = powerManager (“Manager_1”)

Power = (PM_DS.total).Average // watts

W_Avg_x100 = Power * 100.0 // scale to temp below

SEND (output, W_Avg_x100)

Theta_Sum = Theta_JC + Theta_CS + Theta_SA

T_Junction_Numerator = Theta_JA * Theta_Sum

T_Junction_Denominator = Theta_JA + Theta_Sum

T_Junction = TAmbient + ((T_Junction_Numerator/T_Junction_Denominator)*Power)

SEND (temperature, T_Junction)

}

LABEL: BEGIN

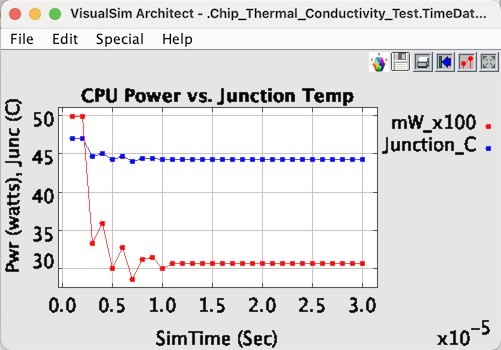

CPU Power, Thermal static calculation plot, after 10 usec no more TG-traffic, goes to Standby; ambient temperature main factor here: